What is a Greenhouse?

Definition: A greenhouse is a structure, typically made of glass or polycarbonate panels, designed for the cultivation of plants in a controlled environment.

The Greenhouse allows the entry of natural light while trapping heat inside, creating a warm and humid environment that is ideal for plant growth. The purpose of a greenhouse is to provide a favorable microclimate for plants, protect them from external factors such as harsh weather conditions and pests, and extend the growing season. Greenhouses can vary in size and design and can be used for various purposes such as seedling propagation, flower and fruit production, and even aquaculture.

Advantages of Greenhouse/Polyhouse

- Multiple crops can be grown throughout the year, increasing the farm's overall productivity.

- Greenhouses allow for off-season production of vegetable and fruit crops, which can fetch a higher price in the market.

- Increased crop productivity can be achieved in greenhouses, as they provide a favorable microclimate for plant growth and development.

- superior quality products can be produced in greenhouses, as they provide protection from external factors such as pests, diseases, and harsh weather conditions.

- Efficient use of various inputs like water, fertilizers, seeds, and plant protection chemicals can be achieved in greenhouses, as they are applied directly to the plants and not wasted due to run-off.

- Effective control of pests and diseases can be achieved in greenhouses, as they provide a barrier against external sources of infection.

- The percentage of germination of seeds is high in greenhouses, as the environmental conditions can be controlled to provide optimal conditions for seed growth.

- The acclimatization of plantlets of tissue culture technique can be carried out in a greenhouse, providing a suitable environment for their growth and development.

- Planning of agricultural and horticultural crop production schedules can be done in greenhouses to take advantage of the market needs and demands.

- Growing mediums like peat moss, vermiculite, rice hulls, and compost that are used in intensive agriculture can be effectively utilized in greenhouses.

- Export quality produce of international standards can be produced in greenhouses, meeting the requirements of the global market.

- Drying and related operations of the harvested produce can be taken up utilizing the entrapped heat in greenhouses, reducing the energy requirements for these operations.

- Greenhouses are suitable for the automation of irrigation, application of other inputs, and environmental controls by using computers and artificial intelligence techniques, increasing the efficiency of the production process.

- Greenhouses provide opportunities for self-employment on the farm, as they require specialized knowledge and skills for their operation and management.

The greenhouse effect is a natural phenomenon that occurs when certain gases in the Earth's atmosphere, such as carbon dioxide, water vapor, and methane, trap heat from the sun's rays, preventing them from escaping into space. This same principle is utilized in a greenhouse to create a warm and humid environment suitable for growing plants.

The basic structure of a greenhouse consists of a frame made of wood or metal, covered with a transparent material such as glass or plastic. The transparent covering allows sunlight to enter the structure, warming the air and soil inside. The air inside the greenhouse is often kept moist, which helps to maintain a humid environment for the plants to thrive.

The temperature inside the greenhouse is controlled by ventilation systems, which regulate the amount of air that enters and exits the structure. This helps to maintain a consistent temperature and humidity level, ensuring optimal growing conditions for the plants.

In addition to controlling the temperature and humidity, greenhouse growers also monitor the levels of nutrients and water in the soil and provide artificial lighting when necessary to supplement natural sunlight. This careful monitoring and management of the growing environment are essential for the successful growth of plants in a greenhouse.

General Types of Greenhouse

- Simple Greenhouse

- Semi-High Tech Greenhouse

- High Tech Greenhouse

Simple Greenhouse

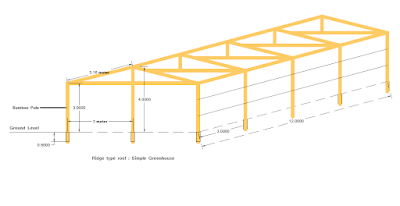

While a dome greenhouse has a curved roof, a flat or peaked roof greenhouse has a roof that is either completely flat or slopes upward to a peak. These greenhouses are typically rectangular or square, with straight walls and a roof that is either flat or peaked. Unlike a dome greenhouse, a flat or peaked roof greenhouse is less unique in appearance but may be more practical for certain types of plants and growing conditions and easier to construct and maintain.

The Simple Greenhouse may include, a simple net house, or a simple dome/peaked roof greenhouse. The general size may be 6*12 m or 8*20 m.

a. Simple Bamboo Greenhouse:

Drawing and Specification

- Curved Roof Simple Bamboo Greenhouse

- Ridged Roof Simple Bamboo Greenhouse

- For plastic/insect net and mulching, 90 GSM or more than 90 GSM Silpaulin Plastic/200 micron UV Plastic is compulsory.

- For small structures, straight, unbroken, and untwisted bamboo is required.

- The middle pole should have a height of 4 meters and the side pole should have a height of 3 meters.

- The foundation depth for the bamboo structure should be 0.6 meters.

- The width limit for the structure should be between 7 to 10 meters.

- The length of the structure can be adjusted based on the available space.

| Earthwork in Excavation | cu.m |

|---|---|

| Bamboo: Side Column | m |

| Bamboo: Middle Column | m |

| Bamboo: Purlin | m |

| Bamboo: Top Chord | m |

| Bamboo: Bottom Chord | m |

| Bamboo: Ridge Cord | m |

| Plastic 90 GSM/200 Micron UV Plastic | sq m |

Figure 6: Ridged Roof GI/Black Piped Greenhouse

Figure 7: Side View of GI/Black Pipe Greenhouse

- For plastic/insect net and mulching, 90 GSM or more than 90 GSM Silpaulin Plastic/200 micron UV Plastic is compulsory.

- A 2-inch Pole/Post should be used in the case of either GI Pipe or Black Iron Pipe.

- The pipe used in a truss or lateral use should be 1 inch in diameter or length (in the case of square pipe).

- The middle pole should have a height of 4 meters and the side pole should have a height of 3 meters or it may vary a little according to the geographical region.

- Pole to pole Distance should be 3 meters.

- The foundation depth should be 0.9 meters with PCC and PCC should be extended to 0.3 m above the ground level.

- Square or round Pipes can be used in poles but in the truss sections round pipes should be used. However, in the truss section of a greenhouse, round pipes are typically used instead of square pipes because they are better able to distribute the weight and stress of the greenhouse evenly across the structure. Round pipes can also withstand greater pressure and bending moments than square pipes, making them a more suitable choice for the truss section of a greenhouse where greater forces may act on the structure. Additionally, round pipes tend to be more resistant to buckling and deformation under pressure, which further enhances their structural integrity in the truss section of a greenhouse. Moreover, for good ergonomics in roofing works, round pipes are used in such greenhouses.

- The width limit for the structure should be between 7 to 10 meters.

- The length of the structure can be adjusted based on the available space.

- Profile locking: In this method, a metal or plastic profile is used to secure the plastic cover onto the greenhouse frame. The profile is attached to the frame using screws or bolts, and the plastic cover is then clamped onto the profile using special locking strips. For GI or black piped greenhouse, a galvanized iron or stainless steel profile is recommended to prevent rusting and corrosion.

- Zigzag locking: In this method, a zigzag wire is used to hold the plastic cover onto the greenhouse frame. The wire is passed through the plastic cover and then looped around the greenhouse frame at regular intervals to create a secure hold. For GI or black piped greenhouse, a wire made of galvanized iron is recommended to prevent rusting and corrosion.

| Item | Description | Specification |

|---|---|---|

| 1 | E/W Excavation in foundation in soft soil | Lift 1.5 m and lead up to 10m all complete as per instruction of site incharge |

| 2 | Providing and laying P.C.C. | Below G.L. 1:3:6 including curing all complete as per instruction of site in charge, Above G.L. |

| 3 | Supply & fixing of MS or GI (whichever applicable) pipes for truss with necessary cutting,welding,painting & fixing all complete as per instruction of site incharge | Side Column Square (38mm38mm) 2mm thick, Middle Column Square (38mm38mm) 2mm thick, Top Chord Square (24mm24mm) 2mm thick, Bottom Chord Square (38mm38mm) 2mm thick, Purlins Square (24mm24mm) 2mm thick, Webs (24mm24mm) 2mm thick |

| 4 | Providing of Green Net for roofing | With necessary fittings all complete as per instruction of site incharge |

| 5 | Providing of Anti Insect Net for Side Covering | With necessary fittings all complete as per instruction of site incharge |

| 6 | Supply and fixing of aluminum profiles | As per instruction of site incharge |

| 7 | Supply and fixing of PVC coated zigzag spring | All complete as per instruction of site in charge |

There are several different types of greenhouses, each with its own unique features and benefits.

Other types of Greenhouses include:

- Lean-to Greenhouses: Lean-to greenhouses are attached to an existing structure, such as a house or a garage. They are typically built against a south-facing wall to maximize exposure to sunlight. Lean-to greenhouses are often smaller than other types of greenhouses, making them a good option for smaller gardens.

- Freestanding Greenhouses: Freestanding greenhouses are not attached to any existing structure and can be placed anywhere on a property. They come in a variety of sizes and shapes, from small dome-shaped structures to large commercial buildings.

- Hoop Houses: Hoop houses are temporary structures that are made of PVC pipes or metal hoops covered with a layer of greenhouse plastic. They are often used by farmers and gardeners to extend the growing season in areas with colder climates. Hoop houses are easy to assemble and disassemble, making them a good option for seasonal use.

- Gable Greenhouses: Gable greenhouses have a pitched roof that is higher in the center than at the sides. They provide more headroom than other types of greenhouses, making them a good option for taller plants. Gable greenhouses are often used by commercial growers and can be quite large.

- Dome Greenhouses: Dome greenhouses are unique in their shape, with a rounded roof that slopes downward toward the ground. They are often used in permaculture gardens and can be quite small or quite large.

- Geodesic Greenhouses: Geodesic greenhouses are similar to dome greenhouses in their shape, but are made of interconnected triangles that provide greater structural stability. They are often used by commercial growers and can be quite large.

Each type of greenhouse has its own unique features and benefits, making it important to choose the right type of greenhouse for your specific needs. Factors such as climate, available space, and intended use should all be considered when selecting a greenhouse.

1 Comments

Good Details

ReplyDelete